Epsilon Carbon Private Limited (ECPL) was established in 2010 with the vision to become the partner of choice and trust in the carbon derivatives market.

Headquartered in Mumbai, Maharashtra, with manufacturing units in three strategic locations—Karnataka, Chhattisgarh, and Odisha—we have achieved complete integration in our operations, with a dedicated source of raw materials. Epsilon Carbon aims to be a global leader in the carbon black (CB) and coal tar (CT) derivatives industry.

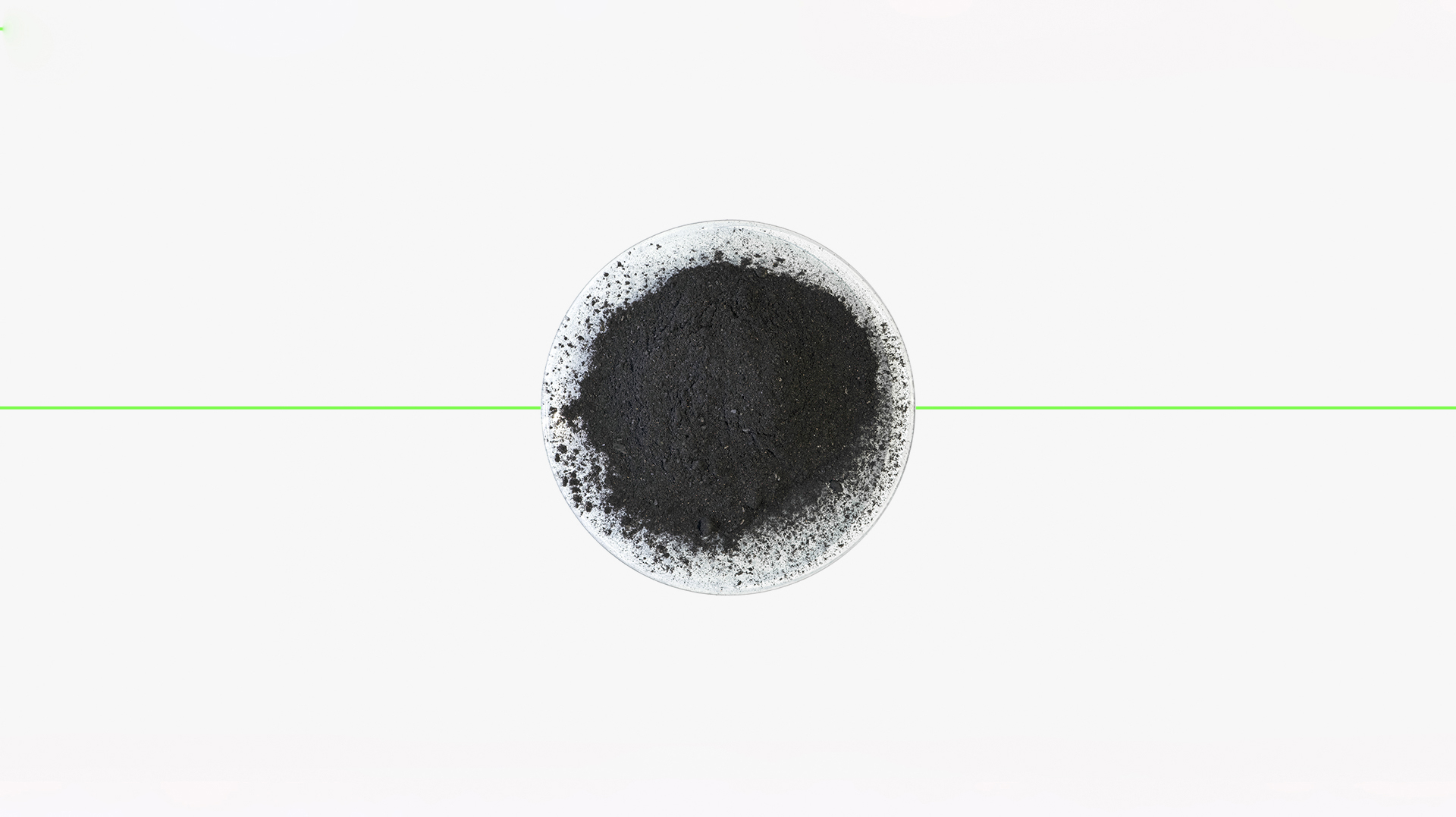

We specialise in manufacturing both reinforcing grades and tread grades of hard carbon black, which find extensive applications across various sectors, including tyre treads and mechanical rubber goods. Our product range includes the 100, 200, and 300 series, which are reinforcing grades suitable for sidewalls and inner liners of automobile tyres, as well as other automobile components like sealing systems, hoses, and anti-vibration components. In addition, we offer semi-reinforcing or carcass grades, represented by the 500, 600, and 700 series, which are ideal for general rubber goods.

Our portfolio of coal tar derivatives serves key industries such as Aluminium, Graphite, Carbon Black, and Specialty Chemicals. We employ advanced manufacturing processes to ensure the delivery of high-quality products while prioritising sustainability.

Our company is led by a dedicated team of experienced industry professionals who combine their expertise to drive operational efficiency and address environmental and social concerns. As our first step towards becoming a global industry leader, we have recently commissioned a state-of-the-art 115,000 TPA backward integrated plant in Bellary. We are committed to further expansion and forward integration, with plans to increase the capacity of our facility to 215,000 TPA in the second phase by 2024.

Our Purpose

Building Blocks of Tomorrow

Young, bold, and ambitious, we are driven by a relentless pursuit of excellence in the services we provide. With a dynamic and passionate team, we are dedicated to pushing the boundaries of what is possible and setting new benchmarks of excellence in our industry.

Our Values

Building on a Strong

Foundation

01.

Innovation

We continuously strive for innovation and progress, finding new solutions to overcome challenges, enhance operations, and expand our company. Efficiency and environmental responsibility form the foundation of all our business.

02.

Passion

Ignited by our passion to learn and succeed enthusiastically every day, we are committed to deliver excellence in our core services.

03.

Quality

We always look for ways to deliver products that will exceed customer expectations.

04.

Integrity

We are courageous, honest, transparent, trustworthy and adhered to the highest ethical standards.

05.

Collaboration

We believe in the spirit of collaboration by maintaining a positive and cooperative relationship with all our stakeholders.

Our Commitment

Living up to our

Promise Everyday

Our code of ethics drives us to maintain systematic and exceptional alliance with all our stakeholders: our people, employees, vendors, customers, and community at large.

Our people are at the heart of our success stories. To ensure their wellbeing, we conduct business in accordance with prevailing government policies and comply with all laws and regulations to stay aligned with our core values.

We adhere to global safety standards to ensure the safety of our employees. Our pricing policies, which are transparent and benchmarked against international indices, as well as our strong customer support, demonstrate our commitment to our vendors and customers.

Our goal is to achieve a neutral carbon footprint and we encourage all stakeholders to adopt environmentally sustainable practices. We continuously work to improve energy efficiency, reduce water usage and minimize waste. Our plants are Zero Liquid Discharge facilities, and 100% of the wastewater generated is collected, treated, and reused on-site. To further minimize pollution, we have undertaken a detailed environmental impact assessment of our plant and developed 44-acre green belt by planting 40,000 saplings to restore the ecological balance.

We are driving long-lasting and sustainable societal change in our operating geographies. Our interventions are aligned with national development priorities and UNSDGs (United Nations’ Sustainable Development Goals). Guided by the expressed needs and development preferences of these communities, we support activities such as education, skilling, employment, health, water conservation, etc., to facilitate their growth and development.

Our Journey

Shaping an

inspiring legacy

- 2017 We established ourselves as

a private limited company - 2019

- 2020

- 2021

- 2022

- 2023

Leadership Team

Setting standards through actions

Meet our team of committed, experienced and agile industry professionals who represent some of the best talent in the industry.

Read StoryRecognised for

Excellence

Each recognition serves as a reminder of our commitment to delivering outstanding results and providing exceptional service to our valued customers.

View more