Safety

Committed to Zero Harm

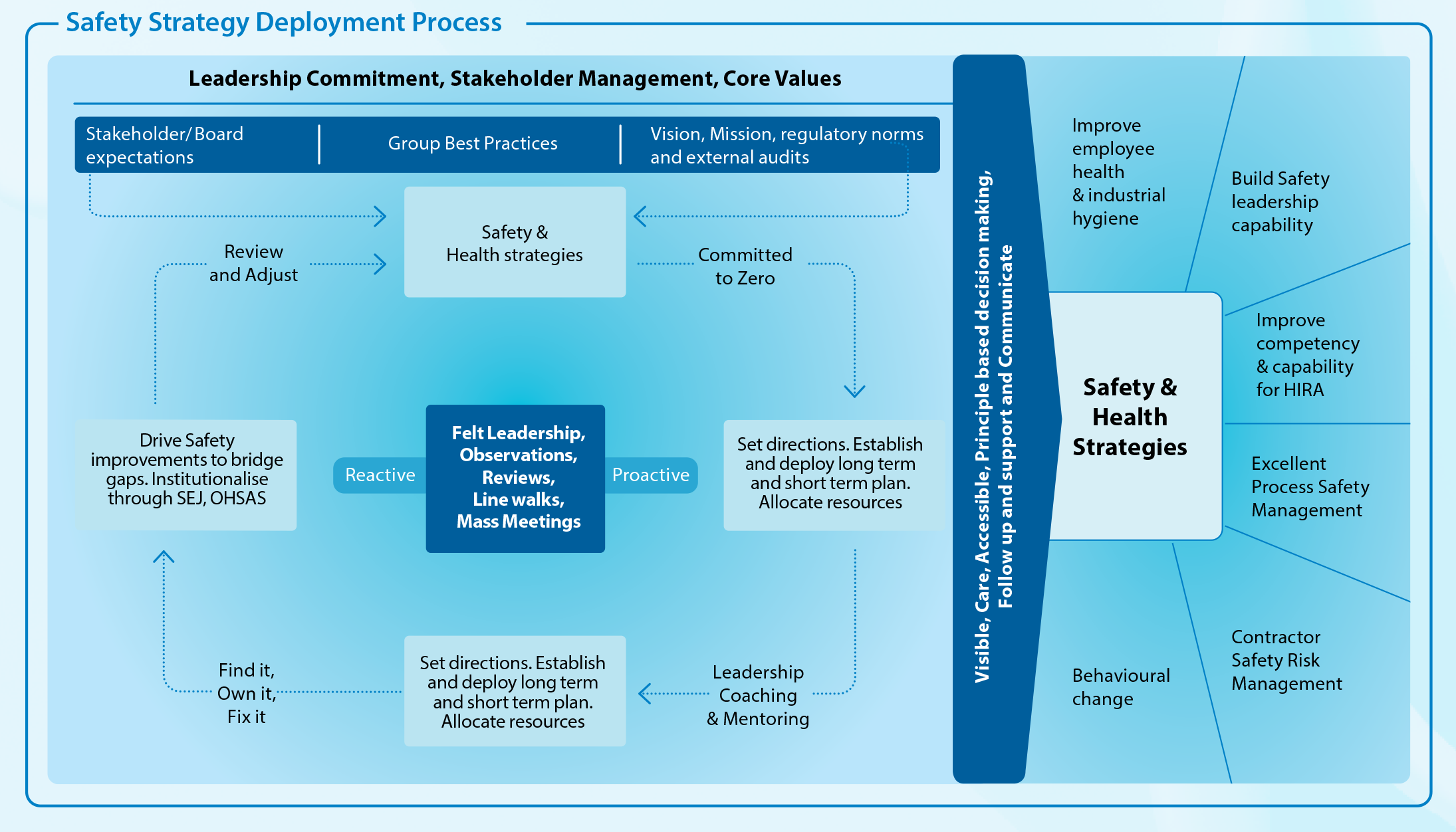

Our Safety and Health responsibilities are driven by our commitment to “Zero Harm” to the people we work with, and the community at large. Our robust Safety Management System framework and the Safety Governance structure, are key drivers in our Safety Excellence Journey.

Established Safety as a Core Value Across the Organisation

We are focused on our commitment to ensuring the well-being of all individuals involved in our work. Our Safety and Health responsibilities are driven by our commitment to “Zero Harm” to the people we work with, and the community at large. Our robust Safety Management System framework and an effective Safety Governance structure, overseen by the Safety, Health, and Environment Committee of the Board, are helping our Safety Excellence Journey.

At Tata Metaliks, the value-based Safety culture and the promotion of risk-based thinking are being strengthened through long-term Safety and Health strategic priorities. Our Goal is to make Safety an essential aspect of the business to attain “Zero Harm”. The action plans stem from Safety and Health strategic objectives at the deployment level, supported by several initiatives in our journey toward Safety excellence.

We are continuing our relentless pursuit to make Safety a non-negotiable aspect of business. The process of culture building over the years by various initiatives are substantiated by continued improved results in several parameters. Personal commitment by Senior Leaders, at all levels, is demonstrated by various actions, Felt leadership and other communication on Safety. Employees continue to be engaged in Safety and Health through Toolbox talk, Mass Meetings, Kaizens, projects, SHE month celebrations, Safety R&R, ‘Shabashi’ and instant rewards among others. Employees are encouraged to raise Safety and Health concerns and duly empowered to stop unsafe work, if required.

We have taken a significant step forward by curating interventions under the overall focus on instilling a culture of consciousness and ownership of Safety among all employees. Our goal is to cultivate a Safety culture where everyone takes personal responsibility for maintaining a secure work environment, embracing the commitment of “I am Conscious, and I am the Owner of Safety”. This collective effort is aimed to pave the way for Safer and more Sustainable operations of our organisation.

Key Safety Indicators

| Particulars | FY 2018-19 | FY 2019-20 | FY 2020-21 | FY 2021-22 | FY 2022-23 |

|---|---|---|---|---|---|

| Fatal Accidents | 0 | 0 | 0 | 1 | 1 |

| Lost Time Injury Frequency Rate (LTIFR) | 0.10 | 0.28 | 0.00 | 0.15 | 0.27 |

| First-Aid Frequency Rate (FAFR) | 5.10 | 4.29 | 2.61 | 2.14 | 1.50 |

| Total Recordable Injury Frequency Rate | 4.95 | 4.60 | 2.61 | 2.30 | 1.78 |

| Total Recordable Work-Related Injuries | 51 | 49 | 25 | 29 | 26 |

| First-Aid Cases | 50 | 46 | 25 | 27 | 22 |

| Near-Miss Cases | 1,285 | 3,250 | 1,970 | 2,557 | 1,985 |

| Safety Training Sessions (Nos.) | 279 | 2,839 | 2,949 | 4,506 | 4,303 |

| Safety Training Person Hours | 16,678 | 34,535 | 24,656 | 48,817 | 41,578 |

| Safety Visits (Nos.) | 4,601 | 6,077 | 7,289 | 7,533 | 7,260 |

Ensuring Contractors’ Safety

We have institutionalised a well-established Contractor Safety Management Standard (CSMS), which governs Contractor Safety at Tata Metaliks. A robust six-step Contractor selection procedure is mandatory to select vendors. This framework has established Policies and Procedures on Safety responsibilities for Contractors and their employees. Through this platform, the Company and Vendor partners collaborate and agree upon actions to be taken on Safety throughout the year.

As part of the CSMS framework, we continue our star rating assessment for the evaluation of contractors. Over the course of this CSMS journey, several Contractors have transitioned from 3-star to 4-star/5-star levels; a testament to our cohesive approach towards strengthening the competence of our Contractor workforce.

Elevating Safety Leadership capability at all levels to achieve ‘Zero Harm’

In line with our organisational objective of Zero Harm, we have made steady progress in the last few years. We remain focused on our Safety objective and are building our Safety leadership and capabilities by investing in learning and digital. Some of the key interventions include:

- Imparted trainings through e-learning and a Virtual Reality module on Safety Standards.

- Imparted ‘Adhinayak’ training for Workers.

- Facilitated ‘Go and See’ different industries and academia to consider adopting the best technologies to enhance Safety enablers.

- Imparted trainings on Process Safety.

- Facilitated skill-based simulation training for various shop floor activities.

- Increased focus on Machine Guarding and LOTOTO.

Promoting Process Safety to enable better results

We continue to focus on improving and going deeper in our actions towards improving our journey on Process Safety. Our process Safety Management focusses on eliminating incidents with the potential to result in multiple injuries, as well as causing substantial economic, property and environmental damage, both within the manufacturing unit and across surrounding communities. A dedicated team continues to focus on process Safety study and we have already covered multiple processes with action plans in both divisions.

Improving employee health and industrial hygiene

At Tata Metaliks, we remained aligned to build a culture of health and well-being. Our comprehensive industrial hygiene programme including the identification of occupational health hazards and risk analysis, assessment of actual exposure through job hazard analysis, and implementation of hazard control measures to maintain minimum exposure level and to reduce occupational health-related risks. Moreover, periodic medical examinations, regular follow-up of high-risk cases, mental well-being programmes, health awareness campaigns to increase consciousness, online doctor facility, are few important interventions carried out.