Innovate and Excel

Relentless

Innovation for a

Sustainable

Future

Priority Areas

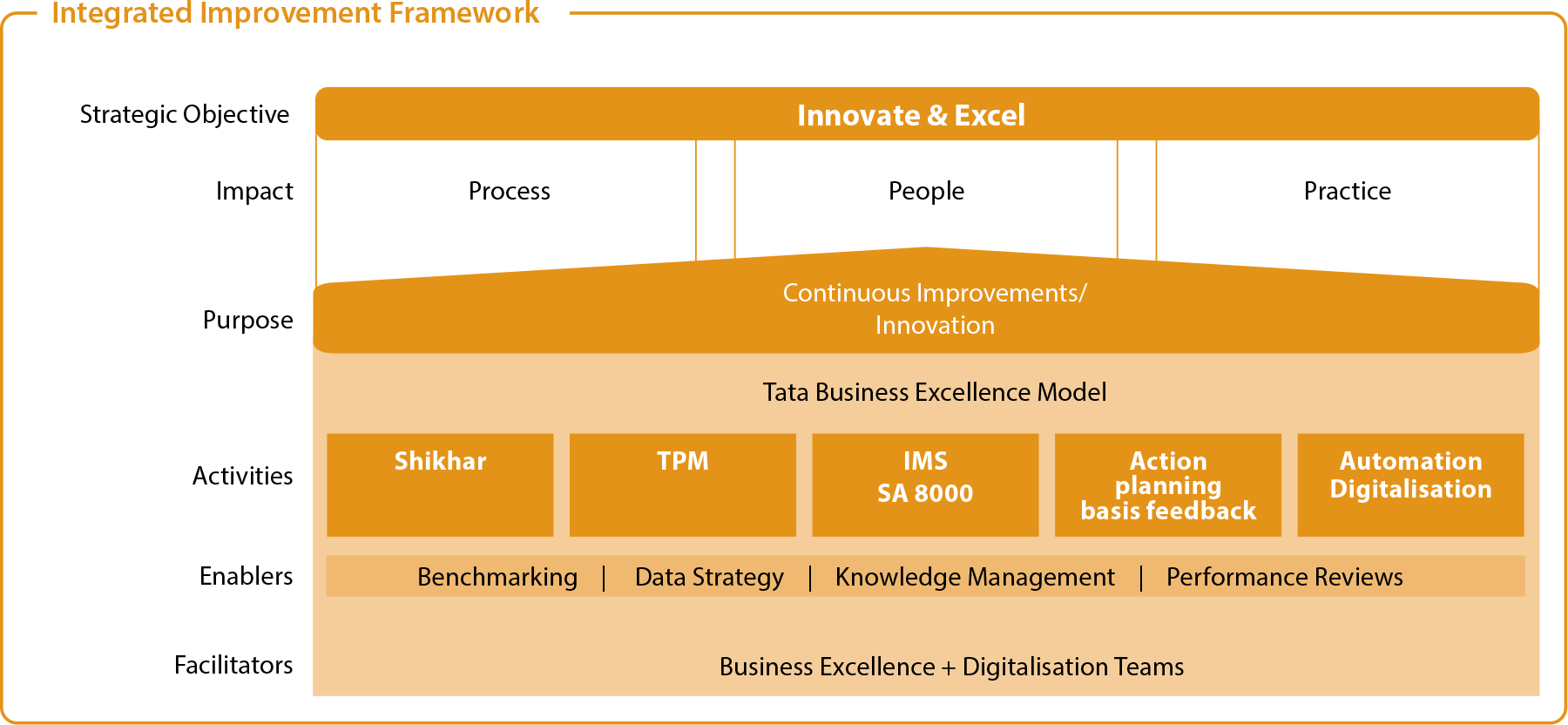

- Benchmarking, TPM at shopfloor, Ideation platform and Knowledge Management

- Process improvement through flagship initiative Shikhar and recently launched Integrated Improvement Programme, aiding EBITDA

- Digital transformation to ensure agility and differentiation

Material Topics

SDGs Impacted

Capitals Impacted

Financial

Manufactured

Human

Intellectual

Natural

We have always followed an ‘innovation-led’ approach in our journey of Business Excellence. This approach has been critical to our success in the past and will also drive our growth in the future. We are on an accelerated journey of Business Excellence with a continuous focus on improvement driven by digital transformation. We are focused on leveraging digital technologies across the value chain while driving a culture of continuous improvement across the organisation.

Accelerating Sustainable Innovation

Our Innovation Framework is instrumental in fostering a culture of agility and innovation within our organisation, ensuring consistent delivery of incremental and breakthrough advancements. Our Ideation platform and new Integrated Improvement Programme (IIP) have democratised the capturing and sharing of ideas among shopfloor employees, while participation in Tata Innovista competitions and leadership encouragement for new ideas have fuelled a culture of experimentation.

An Integrated Improvement Programme (IIP) has been launched with the objective of accelerating improvement projects. Under this programme, more than 800 Ideas have been generated and prioritised for business case preparation and implementation.

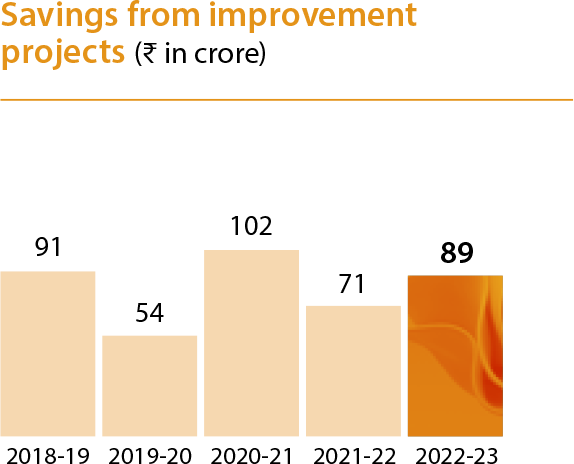

Collaborative group discussions and a culture of sharing and adopting best practices have also sparked numerous improvement opportunities. Shikhar projects, validated by our in-house Business Analysis Group (BAG), resulted in ₹89 crore in savings in FY 2022-23, compared to ₹71 crore in FY 2021-22.

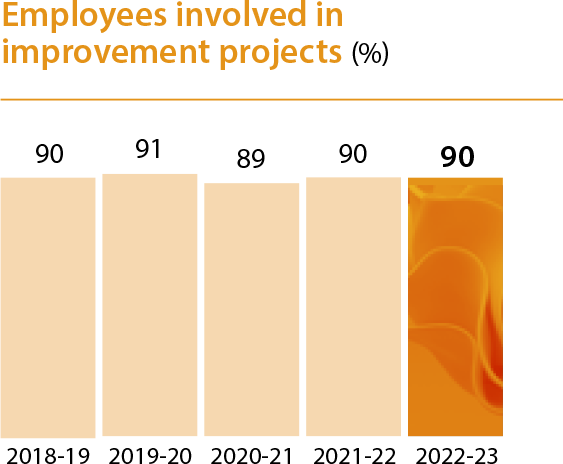

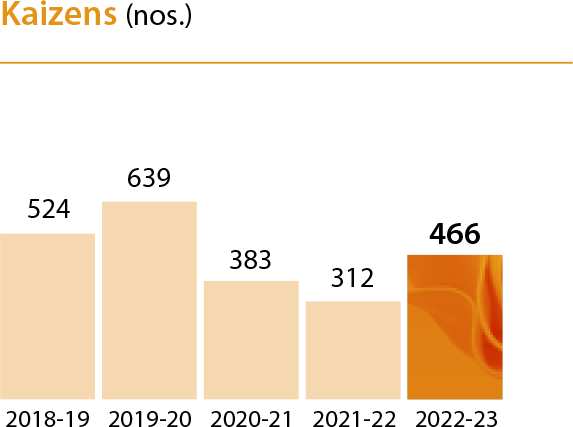

Total Productive Maintenance (TPM) activities have significantly engaged employees and driven improvements on the shop floor. Our consistent success in competitions organised by CII at the state and national levels further motivates us to foster continuous improvement. Leveraging benchmarking, the Ideation platform, Knowledge Management process, and learning and development initiatives, we continue to accelerate our journey toward excellence. The democratisation of ideation allows employees from across the organisation to participate, while collaborations with internal and external Stakeholders, particularly academia, enhance our appetite for learning and innovation.

Our digital transformation journey has yielded significant process efficiencies and tangible changes throughout the organisation. With a focus on real-time data analytics, smart machines, and business on mobile coupled with process improvement, our long-term digital strategy measures outcomes based on Safety, productivity and EBITDA. We implemented strategic initiatives such as Energy Management System, Manufacturing Execution System, Level II Automation System for MBF#1 etc. Project ARUNA, aimed at EBITDA-accretive data analytics, has contributed to savings of about ₹25 crore for digital projects in the overall Shikhar savings.

A notable accomplishment in our digital journey has been the successful commissioning of Phase 1 of our new DIP project using Augmented Reality (AR) due to travel restrictions. The plant, designed based on Industry 4.0 principles, incorporates a high degree of automation. We will deploy similar resources in commissioning our Phase 2 of the project. We have also strengthened our robotics capability and developed pioneering in-house robotics solutions in the DIP industry.

Powering Data Analytics

Data analytics has emerged as a key focus area in our digital journey, leading to the initiation of various Data Management and value creation use cases in recent years. We have successfully implemented several data analytics projects utilising AI/ML techniques across different business domains.

Relentless Innovation

We have a well-defined pipeline of structured initiatives aimed at achieving both incremental and breakthrough innovations, with several of them being industry firsts. Some of our major completed and ongoing interventions include:

- Implementation of robots in the DIP plant to enhance Safety, productivity and efficiency.

- Utilisation of AR technology for remote commissioning of our new DIP unit, overcoming travel restrictions.

- Successful implementation of Phase-I of CRM solutions specifically designed for our DIP Business.

- Creation of virtual/augmented realitybased platforms for remote maintenance and training purposes.

- Deployment of an AI/ML-based analytics programme known as Project ARUNA, which has delivered substantial EBITDA savings through various implemented use cases.

- Collaborations with esteemed academic institutions.

- Synergistic partnerships with Tata Steel R&D to drive innovation and technological advancements.

Way Forward

With a clear roadmap, our future direction will be guided by the key pillars of digitalisation, mindset transformation and a culture of innovation. Our Integrated Improvement Programme will play a pivotal role in enhancing our process efficiencies, quality, Safety and productivity. The ongoing implementation of automation initiatives and analytical interventions across various processes will not only enhance behavioural Safety but also enable agile decision-making and improve workforce productivity. We are committed to embracing these transformative changes to drive continuous improvement and achieve our organisational goals.