Focus on Downstream/Value-add

Enhancing our

Scale and Scope

Priority Areas

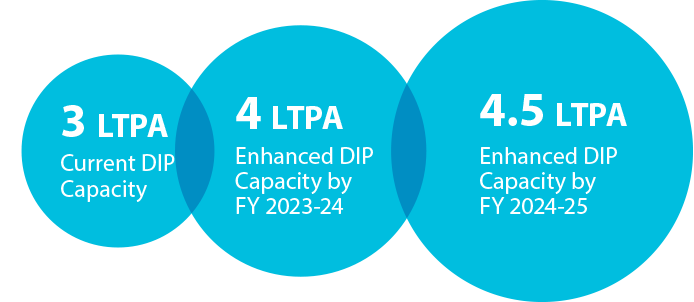

- Capacity expansion for DIP to over 4 LTPA

- Extend domestic footprint

- Enhance presence in different geographies

Material Topics

SDGs Impacted

Capitals Impacted

Financial

Manufactured

We are expanding our value-added downstream business portfolio to better cater to the water infrastructure sector of India. Our brownfield expansion project is currently in progress, and upon completion, we aim to more than double our DIP capacity. This will enable us to capitalise on the growth opportunities available in the market.

DIP: Sustainable Value-added Product

DI Pipe finds wide usage across various applications in the water and sanitation sectors. Their flexible push-on joints have the unique ability to not leak at high pressure, even when deflected, making them easy to lay and join. DIP is anti-corrosive by virtue of its unique physical properties through external zinc and bitumen/epoxy coatings and has high tensile strength, enabling it to handle higher pressure and stress compared to traditional cast iron pipes. Additionally, DIP offers higher beam strength, resistance, and traffic load, making it technically and environmentally superior to non-metallic pipes.

Sectoral Opportunity

India, with 18% of the world’s population, only has access to 4% of the world’s water resources, making it one of the most water-stressed countries globally. According to a recent report by the NITI Aayog, the Government’s policy thinktank, a large number of Indians face high to extreme water stress. This challenge is exacerbated by India’s dependence on an increasingly erratic monsoon for its water requirements, which is expected to worsen due to climate change. Furthermore, the frequency and intensity of floods and droughts in the country are likely to increase.

In response to these challenges, the Jal Jeevan Mission was launched with the vision of providing safe and adequate drinking water through individual household tap connections to all rural households by 2024. This initiative, in partnership with the states, provides a significant opportunity for the DIP industry to support the huge and deprived rural Indian population.

Moreover, the Indian Government has also announced the JJM Urban and Swachh Bharat 2.0 initiatives to be completed over the next five years, resulting in a corresponding increase in the central budget for the water and sanitation sectors. Significant state-led investments have also been made in the irrigation sector. With such a large scale of proposed investment by the Central Government and States in the water sector, the pipe industry, in general, and the DI pipe industry, in particular, is poised for significant growth in the coming years.

Expansion Roadmap

DIP Capacity Expansion

We have successfully completed the first phase of commissioning our new DI pipe plant located in Kharagpur which has not only enhanced the capacity by 50% but also included pipes of diameter up to 1200 mm. We are among the few companies in India to have utilised AR/VR technology to commission a manufacturing unit of this scale. We have built this plant on Industry 4.0 principles, incorporating high levels of automation, mechanisation and digitalisation which makes the plant safe to work and operate.

Way Forward

The demand for Ductile Iron Pipes is expected to grow significantly due to the increasing Government spending on water infrastructure. To meet this demand, Tata Metaliks has already initiated the capacity expansion process and is now expanding its product range in terms of diameters, classes, and linings/coatings. This strategic move will allow us to broaden our scope of participation in the water infrastructure ecosystem while targeting new geographies and customers, thereby strengthening our ‘Tata Ductura’ brand leadership at the marketplace.